Products & services

If you’re seeking a trusted, reliable, plastic materials manufacturer, then you’re in the right place. Whether you need custom colours, special effects, functional additives, a niche compound or a speedy, off-the-shelf colouring solution, Broadway can help.

We’re proud to provide high-quality masterbatches, compounds and rotational moulding powders, delivered with fast lead times. Our customers can expect attentive service and expert technical support. Whether you know exactly what you need, or if you’re less experienced and require a little expert guidance, our friendly team are happy to help.

Reasons to use Broadway

- Fast lead times – next day deliveries achievable

- Consistent, accurate products of premium-quality

- Cost-efficient formulations, providing competitive prices

- Experts in colour matching and customised solutions

- On site colour matching service – great for colouring PCR

- Impressive special effects portfolio

- Comprehensive range of performance additives

- Extensive testing facilities and rigorous QC procedures

- Low minimum order quantities

- Call-off and consignment stock services

- Current European food, toy, medical and REACH compliance

- Excellent customer service from knowledgeable, friendly staff

- Established, family-owned business, trading internationally

- ISO9001, ISO14001 and ISO45001 certified supplier

Greener solutions from your colouring experts

We offer a range of products and services to support customers in achieving their sustainability goals. In addition to the below we can also develop masterbatches with a PCR carrier resin, as well as PCR-based compounds. If there’s something else you’re looking for then please get in touch to discuss your requirements.

MasterFoam

The more you use, the more you’ll save!

MasterFoam is our endothermic blowing agent masterbatch. 🫧

Blowing agents create a foaming effect in the moulding material during production, allowing air pockets into the moulding. The main purpose of blowing agents in plastic manufacturing is to reduce the density of the moulding material. MasterFoam relies on an endothermic reaction, this is less hazardous and more environmentally friendly than widely available exothermic blowing agents. Developed by our in-house technical team, MasterFoam has been extensively trialled and is proven to reduce costs and achieve other important benefits in the manufacture of plastic components:

✅ Reduction in material usage

✅ Reduction in costs, without any tooling changes

✅ Reduction in weight of the moulded component

✅ Reduced cycle times

✅ Reduced energy demand

✅ Reduced carbon footprint of the component

✅ Increased shot/running speed

✅ Increase in productivity (up to 100%)

✅ Prevention of sink marks in the moulded component

✅ Improved strength-to-weight ratio of the moulded component

✅ Improved thermal efficiency of the moulded component

✅ Improved acoustic insulation of the moulded component

Effective at low addition rates, the additive costs less than the value of the polymer saving it provides, so it has a real commercial appeal. In effect, the more a customer uses, the more they’ll be saving! With any further savings from reduced taxation, production efficiency, energy reduction and transportation coming in addition to this. Our extrusion grade blowing agent MasterFoam–Ex doubled the running speed of a customer’s extrusion, effectively doubling the capacity of their operation, without the need for any capital investment. These benefits were proven with a number of successful trials throughout 2023.

MasterFoam is a made to order product, produced at our Suffolk factory – offering security of supply. We’re able to offer FREE material samples for line trials, along with technical support to help you achieve the optimum results.

Other advantages for the customer over thin-walling or resizing the component are that there are no tooling costs, no changes to filling and packaging lines and no changes to the product’s appearance. Lightweighting components, without significantly reducing wall thickness and strength, can offer great benefit in various market sectors where plastics play a vital role, including automotive, aerospace, construction and logistics.

Odour Neutraliser

Reduce odours in smelly materials

Whilst there are obvious circularity advantages to using recycled materials, there are challenges too, such as the smell! Recycled plastics can come from a range of sources and carry a multitude of contaminants, many of these cause odours which are problematic during production and can remain present in the end component. Even some virgin plastics can carry smells which need eliminating. Whilst these can be masked with a fragrance, this isn’t always desirable, particularly in applications such as toiletries or food packaging. It’s also a temporary solution, which soon fades, meaning end products can still present undesirable odours.

Our R&D scientists invested months of research, exploring odour neutraliser additives for plastics. They consider these a more effective and permanent solution than attempting to mask smells with a fragrance. Specialist chemicals within our new odour neutraliser additives act to absorb and trap VOCs and other odour molecules. This significantly reduces the amount of odorous particles which are released, therefore reducing the perceived smell of the material. We’ve explored a number of functional additives in order to find a commercially viable solution which delivers optimum performance.

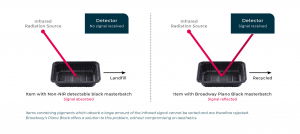

NIR-Detectable Black

Improve recycling compatibility with our NIR detectable ‘piano black’ masterbatches

High opacity, high gloss black plastics are a popular packaging choice, commonly used to offer products a premium appearance. Carbon black pigments – traditionally utilised to achieve such a finish, present inherent difficulties to the NIR detection systems used at waste sorting plants. They are strong absorbers of radiation both in the visible and infrared regions. This limits the amount of infrared radiation which can be reflected into the NIR detectors, placing considerable limitations on the system’s ability to characterise and sort the polymers. Conservative estimates from industry indicate that 30,000 – 60,000 tonnes of black plastic packaging may be entering the UK waste stream each year as a result of this issue.

The in-house laboratory at Broadway has called upon its extensive experience in colour chemistry to overcome this technical barrier. Our NIR-detectable piano blacks have undergone extensive and successful in-house NIR spectroscopy based tests, returning a distinct and statistically significant spectroscopic signature. Compatible with both PET and PP, these masterbatches produce a high-quality gloss ‘piano’ black finish whilst meeting standard food contact regulations. It redefines what can be achieved when it comes to maintaining a premium appearance, whilst safeguarding the ability to sort the end component in standard recycling waste streams.

Colouring PCR

We’re experts in colouring recycled material

With the world focused on reducing plastic waste; brand owners, moulders and consumers are rightly seeking sustainable options. PCR (Post Consumer Recycled) plastics offer an obvious solution – reprocessing waste packaging into usable materials for re-moulding. Our colourists are well-versed in colouring PCR, our team delivers dozens of matches for use in recycled plastics every week.

Many brands already enjoy the benefits of working directly with us. Broadway’s colour suite allows you to join us on-site to approve matches. This process means several new colour samples can be approved in a single day, saving time on product development. This facility is particularly useful when colouring recycled plastics. Our team can use a sample of your base material to demonstrate exactly how a specific batch of recyclate will impact the end colour of your moulded component. We’ll produce samples whilst you wait.

Precision Pigment Placement

Our expert colourists have produced over 50,000 custom colour matches. Our team will take a number of important criteria into account when selecting pigments or dyestuffs for your formulation. These include heat stability, polymer compatibility, lightfastness, toxicity, metamerism, colour criticality and cost.

Our Colour Suite

Broadway’s colour suite allows moulders, designers and brand owners to join us on-site to approve their matches. With access to our friendly team and expert colourists, this process saves precious time and money on development as several colours can be developed, reviewed and approved in a single day. Recent upgrades offer you further insight into our process. A window to our brand new laboratory allows sight of our colourists at work, formulating your colours.

This facility provides the perfect solution in response to the ever increasing demand for colouring PCR (post-consumer recycled) material. Using sample material from your specific batch, our team can demonstrate how PCR content will impact the colour of the end component. Our impressive wall displays showcase a large variety of colours, special finishes and end products – providing extra inspiration should you need it. Our knowledgeable team will be on hand to offer support each step of the way. With free Wi-Fi available, your office is never too far away, but you’re welcome to just sit back and enjoy the coffee whilst we do all the hard work for you.

“Color is a power which directly influences the soul”

Wassily Kandinsky

What is masterbatch?

Why do I need masterbatch?

What is the cost of Broadway’s colour matching service?

Can I get a free sample?

How long will it take for my order to be dispatched?

What are the minimum order quantities for Broadway’s materials?

Which polymers do Broadway manufacture masterbatches for?

Which polymers are Broadway’s Universal Colour Range compatible with?

Which polymers can Broadway compound?