Our new blowing agent masterbatch – MasterFoam, was extensively trialled throughout 2023. The material, developed by our in-house technical team, allows moulders to achieve notable reductions in polymer usage and cycle times. This saves money, reduces the weight of components and can improve their carbon footprint too.

How does it work?

Broadway’s MasterFoam is a chemical foaming agent (also known as a blowing agent). MasterFoam instigates a reaction which creates a foaming effect whilst the material is in a liquefied state during the moulding process. The foam expands as the thermoplastic cools in the mould. This process offsets the tendency for the moulded part to shrink whilst cooling, thus reducing sink marks.

As the material hardens, a fine, regular foam structure forms within it, reducing its density. This means less polymer is needed to fill the mould cavity, therefore less material is required to complete the production run, reducing material costs by almost 10% in many instances. As a result, the moulded component is lighter, which of course offers obvious advantages in a variety of applications.

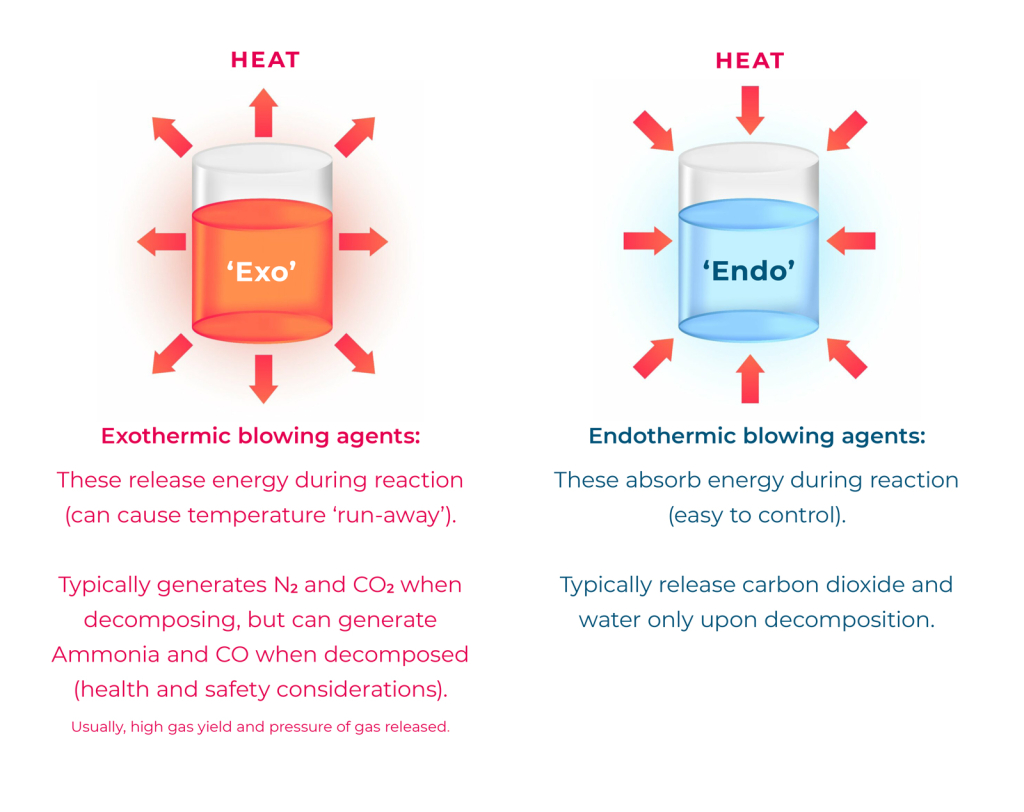

MasterFoam is an endothermic blowing agent. Endothermic blowing agents absorb energy during the reaction process, so the reaction is easy to control. They typically only release carbon dioxide and water upon decomposition. This is a much safer product than widely available exothermic blowing agents.

What are the benefits?

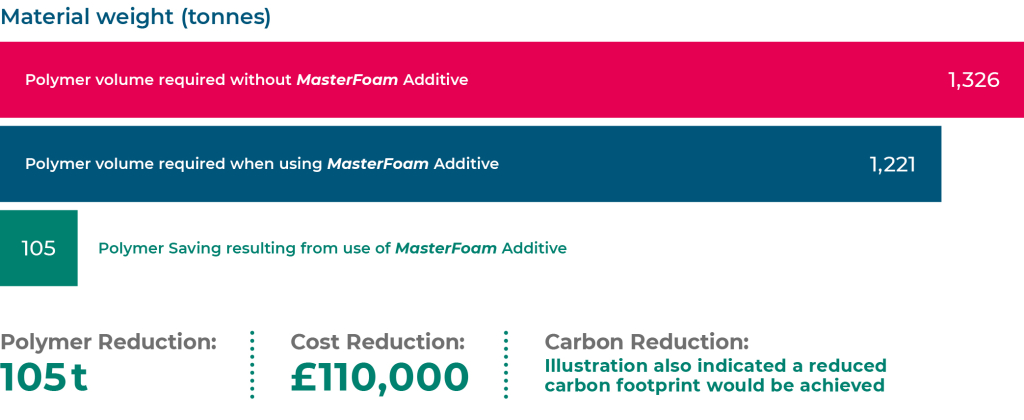

MasterFoam offers many benefits. The application, polymer type and moulding conditions will determine which are achievable, and to what extent in each moulding. Following successful trials, an industry partner suggests they could save 105 tonnes of polymer over a five year period in just two small packaging components, moulded for a leading multinational consumer goods company. They state this would result in a saving of £110,000 on material costs alone. For packaging components subject to the UK Plastic Packaging Tax (the rate of which is due to rise again in April), MasterFoam offers a further cost benefit due to the reduction in the volumes of polymer processed.

Viscosity of the MasterFoam melt is lower than polymer on its own. This is due to bubbles beginning to form in the melt allowing for deformation. This lower viscosity results in a smoother, quicker injection stage. Shot speed is increased as the polymer must be ‘short shot’ into the mould (i.e. less polymer added), to allow a uniform expansion of the foam in the mould. Cooling times typically are reduced, all of which contributes towards a reduced cycle time and reduced energy demand and costs.

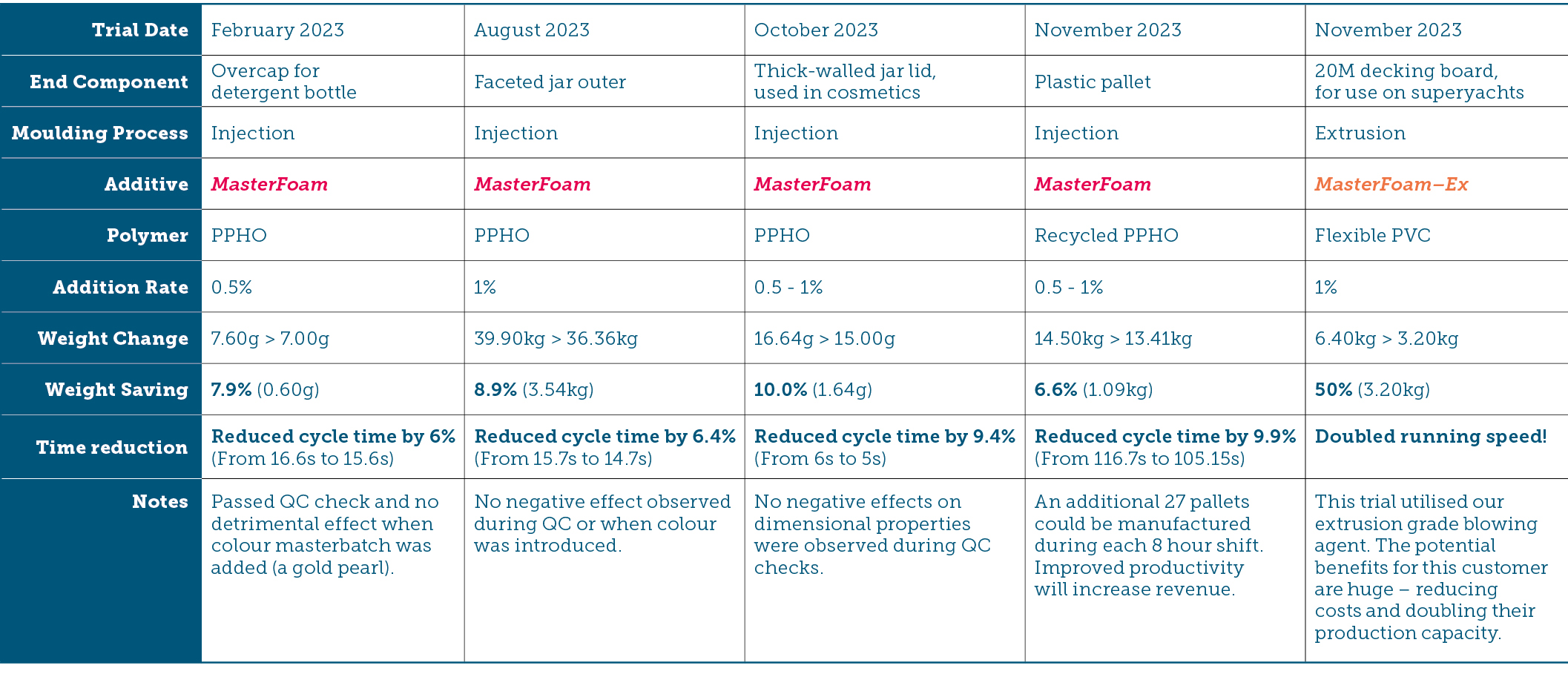

In extrusion moulding trials, the use of our extrusion grade additive – MasterFoam-Ex, doubled the running speed of a customer’s extrusion. This effectively doubled the capacity of their operation, without any capital investment in upgraded infrastructure. The reduced component weight was also highly beneficial for their end application – the potential for this customer is huge.

Another advantage is that the open cell structure offers improved acoustic and thermal insulation properties. This would be particularly beneficial in applications used in construction (such as window frame profiles) where there is increasing scrutiny on thermal efficiency.

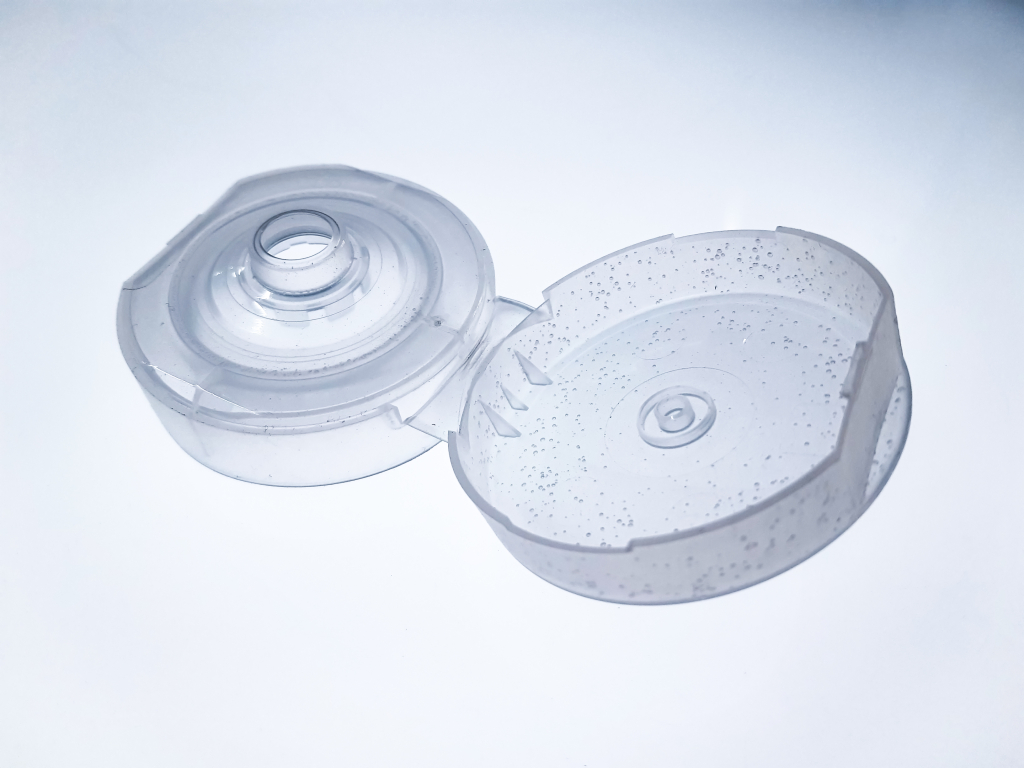

Bubbles evident in a cap moulding, manufactured using Broadway’s MasterFoam. The bubbles are masked when colour is added.

Summary of MasterFoam benefits

- Reduction in weight of the moulded component

- Reduction in material usage

- Reduction in costs, without any tooling changes

- Reduced cycle times

- Reduced energy demand

- Reduced carbon footprint of the component

- Increased shot/running speed

- Increase in productivity (up to 100%)

- Prevention of sink marks in the moulded component

- Improved strength-to-weight ratio of the moulded component

- Improved thermal efficiency of the moulded component

- Improved acoustic insulation of the moulded component

Trial results

Over the past year, we carried out a series of trials with different moulders. These covered various end applications in injection moulding trials using MasterFoam, as well as extrusion trials using MasterFoam – Ex. See the table below showing a summary of results from some of the completed trials.

As you can see from the table of results, our blowing agents have proven to offer a multitude of benefits in both injection and extrusion moulding processes, at low addition rates. Supplied in masterbatch form, the cost of the additive is less than the value of the polymer saving it provides, so it has a real commercial appeal. In effect, the more a customer uses, the more they’ll be saving! And this is before any additional savings in energy, production efficiency, transportation and tax are considered.

Broadway’s Technical Manager, Dr Stephen Rayner during trials at a customer site

“MasterFoam allows our customers to achieve ‘more for less.’ This product provides a significant weight saving in the final moulded component, meaning less polymer is required. We’ve been delighted with the results we’ve seen from customer trials over the past year and we welcome new enquiries for MasterFoam trials. We’re continuing our sustained effort to expand our product portfolio with new offerings which support customers in achieving their commercial and sustainability goals.”

Dr Stephen Rayner, Technical Manager

Why should I use Broadway’s blowing agents?

Our injection grade chemical foaming agent – MasterFoam, is not an imported or traded masterbatch. It was developed in-house by our technical team. It’s a made to order material – manufactured in the UK at our factory in Suffolk, offering fast turnarounds and security of supply. In 2023, MasterFoam produced the best results in independent trials, against a number of competitor blowing agents.

But don’t just take our word for it. We recommend running a material trial to see the benefits for yourself. Free samples can be made available for line trials and we can also provide expert technical support to help you achieve the optimal results. To learn more, or to request a free trial of Broadway’s MasterFoam, please get in touch with our friendly team: email sales@broadwaycolours.com or call 01986 875 100