Broadway has formed a strategic partnership with Black Swan Graphene. A collaboration which brings the benefits of this incredible material to plastic manufacturing via GrapheneXcel – Broadway’s new, graphene-enhanced masterbatches. We spoke to Michael Edwards, COO and Director of Black Swan Graphene Inc, who explained more about graphene and its attributes.

Michael, please can you give us a brief introduction to Black Swan and its strategic aims?

“Black Swan Graphene specialises in the large‐scale production and commercialisation of patented high‐performance and low‐cost graphene products. Formed in 2021, Black Swan acquired patents and know-how from a pioneer in the graphene field – Thomas Swan & Co. Black Swan is now a global leader in the development and supply of graphene nanoplatelets (GNP) for use in new and emerging technologies, bringing the qualities of graphene to various industrial sectors, including concrete and the plastics industry.”

What exactly is graphene?

“Just 20 years ago, at the University of Manchester, Andre Geim and Konstantin Novoselov achieved a groundbreaking milestone. They isolated and identified single-layer graphene using a simple method: exfoliating it from bulk graphite using adhesive tape. For this achievement, they were later awarded the Nobel Prize in Physics in 2010.

Much like diamond and graphite, graphene is an allotrope (a specific arrangement of an element’s atoms) of pure carbon. Extracted from graphite, it consists of just a single layer of atoms arranged in a honeycomb nanostructure. Graphene is classed as a two-dimensional (2D) material because its structure is only one layer of atoms thick. The suffix ‘ene’ reflects the fact that graphene’s allotrope contains numerous double bonds. The extraordinary properties of graphene are due to its unique atomic structure. Graphene offers beneficial characteristics such as strength, electrical conductivity, transparency and barrier properties, making it a highly promising prospect for various technological advancements.”

How does Black Swan produce graphene?

“So-called ‘graphenes’ come in several forms. Black Swan manufactures graphene nanoplatelets (GNP) using our proprietary, patented high shear liquid phase exfoliation (HSLPE) process. Our focus is on volume production, or ‘bulk graphene.’ A scoping study of our modularly scalable process, to be carried out in Quebec, Canada, indicates production potential of 10,000 tonnes per annum. We currently have 40 tonnes of capacity available.”

Black Swan has chosen Quebec as a preferred manufacturing location due to the renewable and low-cost hydro-electric power availability, alongside proximity to partner Nouveau Monde Graphite – one of our key graphite sourcing partners, from which our graphene is produced.”

How did you assess the potential demand for new graphene-enhanced masterbatches?

“We’ve seen significant interest from the plastics industry in adopting our GraphCore™ 01 powder within polymers, but customers struggled with the challenge of handling graphene powders. The process was messy and it was hard to dose and disperse the graphene accurately. Our solution is a real GEM (graphene-enhanced masterbatch). A non-disruptive supply chain approach that allows the industry to work with existing infrastructure. Our partnership with Broadway has resulted in graphene-enhanced masterbatches, offering compatibility with a wide variety of polymers, and they’ve now become a new GEM preferred partner.

The finished material is pelletised and is therefore easy for the customer to handle and process. As an established and trusted UK masterbatch manufacturer, Broadway is well placed to bring the wonders of graphene to a varied customer base in plastic manufacturing through high-quality graphene-enhanced masterbatches. Their in-house technical team has been integral to the development process and is also able to offer expert support to moulders on a case-by-case basis.”

Can you talk us through the development process?

“A lot of hard work and technical expertise has gone into bringing the product to market. The development of Black Swan’s graphene nanoplatelets has been ongoing for over ten years. As a member of the Graphene Engineering Innovation Centre (GEIC) at the University of Manchester, we have carried out multiple trials in their industrialisation incubator facility. This allowed us to perfect our GraphCore™ 01 formulation. Through industrial customer trials we could then optimise our production to provide fully qualified, ISO-controlled processes at our manufacturing plant.

Now through a new partnership with Broadway, the non-disruptive path to the polymer supply chain community is open. Thanks to the availability of our graphene and Broadway’s operational capability, customers can trial GrapheneXcel immediately. Large volumes can be manufactured with quick turnarounds, to meet high-volume requirements.”

What are the key benefits of incorporating Black Swan’s graphene nanoplatelets into plastics?

“Black Swan’s low cost and high performance graphene provides the following benefits on an industrial scale:

- Improved mechanical strength

- Increased impact resistance

- Weight reductions

- Impressive barrier properties

- Enhanced flowability for improved component consistency

- Increased thermal conductivity

- Other benefits such as fire retardancy”

Improved mechanical strength can be of great benefit. Can you tell us more about how graphene enhances mechanical strength in polymers?

“As a single layer, Graphene is the strongest material ever measured, with a tensile strength 200 times greater than steel. Black Swan’s graphene nanoplatelets (GNP) offer mechanical property enhancements such as improved strength and durability. The use of a graphene-enhanced masterbatch increases the elastic modulus of plastics, making the material more resistant to deformation.

Broadway’s GrapheneXcel allows Black Swan’s graphene to be incorporated into plastics in the same way that other additives are. At addition rates of 1% and below, graphene can significantly enhance plastics, making moulded components much stronger and more durable.

Despite its strength, graphene is incredibly lightweight. In the case of plastics, it can allow component wall thickness to be reduced, whilst retaining or even increasing strength. This facilitates lightweighting and polymer reductions, especially beneficial in applications such as packaging where these are key considerations. This characteristic is also ideally suited to the automotive sector and particularly EVs, where every opportunity to reduce weight has a positive impact on the vehicle’s range.”

Can you give some specific examples of the improvements you’ve seen?

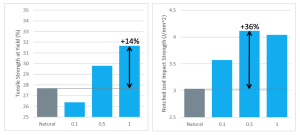

“Typically we see the loading of GNP at around 1% in the final application, and often much lower. In the case of most PP and PE applications seen to date, enhancements of over 10% in parameters such as impact resistance, tensile strength and elongation are achievable, with a GNP loading of just 0.2 to 0.5%.

Three specific examples spring to mind:

1. With a 1% loading in TPU, we were able to increase the tensile strength of our customers’ extruded sheet by over 25% – increasing elasticity and other mechanical features.

2. With polypropylene we’ve seen a 20% improvement in impact resistance with a loading of 0.5%.

3. In addition to strength improvements, in PLA we’ve demonstrated a 40% improvement in barrier properties with an addition rate of just 1%”

Enhanced mechanical properties at different addition rates in polypropylene – Credit: Black Swan Graphene

Can graphene be used in recycled plastics and bioplastics which are increasingly favoured for packaging?

“Our partnership with Broadway offers some exciting paths in the areas of packaging and sustainability. The properties of bio-based and recycled polymers can be improved by adding graphene. Often these types of plastics will suffer from reduced mechanical strength, so the use of a graphene-enhanced masterbatch can counteract this. This has increasing relevance with PCR and bioplastics being more widely used in packaging and single use applications.

Through Broadway’s existing relationships with leading bottle moulders, we’ve explored the benefits of adding graphene nanoplatelets to PET bottles made from 100% ocean prevented [recycled] plastic. Even at low levels, improved barrier properties were apparent – this attribute offers great potential for the packaging of perishable goods.

We’ve also explored the use of graphene-enhanced masterbatches in PLA (polylactic acid) – a biodegradable and bio-based polymer, derived from renewable resources like corn starch or sugarcane. The future is exciting and together we have a GEM of a solution!”

Does the new partnership with Broadway offer any other opportunities?

“Traditionally, incorporating GEMs limits the colour of end components to blacks and dark greys. However, Broadway’s colouring expertise unlocks new possibilities. They’ve shown the ability to achieve a variety of colours in mouldings that include graphene at modest yet effective levels. Although the inherent tint of graphene still restricts the range of achievable colours, this advancement significantly expands the potential applications for GEMs.”

Can you tell us about your experience of collaborating with Broadway?

“We are delighted to partner with Broadway. The adoption of our GNP into their masterbatch has been straightforward and the technical team’s support has been first-class. The laboratory facilities and established academic partnerships lead to further progress quickly. We are delighted to partner with such a positive, forward-looking business and delighted to welcome them to our GEM channel.”

Broadway’s Technical Director, Dr Stephen Rayner added:“Strategic collaborations with trusted supply partners like Black Swan and leading academic institutions such as the Graphene Engineering Innovation Centre (GEIC) have forged a transformative journey for Broadway. By combining their cutting-edge expertise in graphene with our deep manufacturing and technical proficiency in polymers, we’ve successfully launched GrapheneXcel. This new addition to our ‘+performance’ range of performance-enhancing masterbatches delivers significant benefits to customers across several market sectors.”

Get in touch to learn more about Broadway’s graphene-enhanced masterbatches:

Call 01986 875 100 or email sales@broadwaycolours.com